Breaking Waves and Boundaries: IEV’s Triumph in Accelerating Jetty Pile Maintenance with Innovative Marine Growth Preventers in Peninsular Malaysia

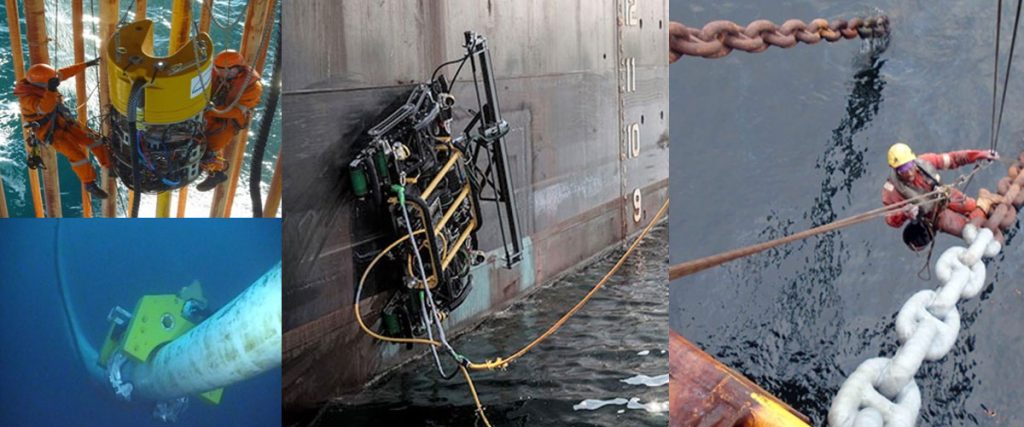

In June 2023, IEV secured a significant contract to install its innovative Marine Growth Preventers (MGP) on 1,294 jety piles for a prominent terminal operator in Peninsular Malaysia. This demanding project requires the completion of a comprehensive scope of work within a stringent 5-month delivery timeline. This included a particularly challenging two-month period dedicated to […]