Asset Integrity Management

We offer a range of disruptive technologies as an individual services or integrated engineering solutions to deliver optimum and cost-effective solutions to inspect, assess, repair and maintain assets.

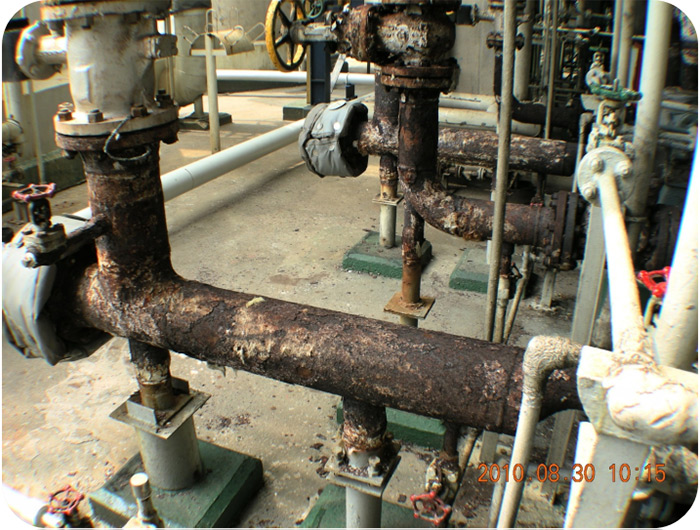

CORROSION UNDER INSULATION MANAGEMENT SOLUTIONS (CUIMS)

CORROSION UNDER INSULATION MANAGEMENT SOLUTIONS

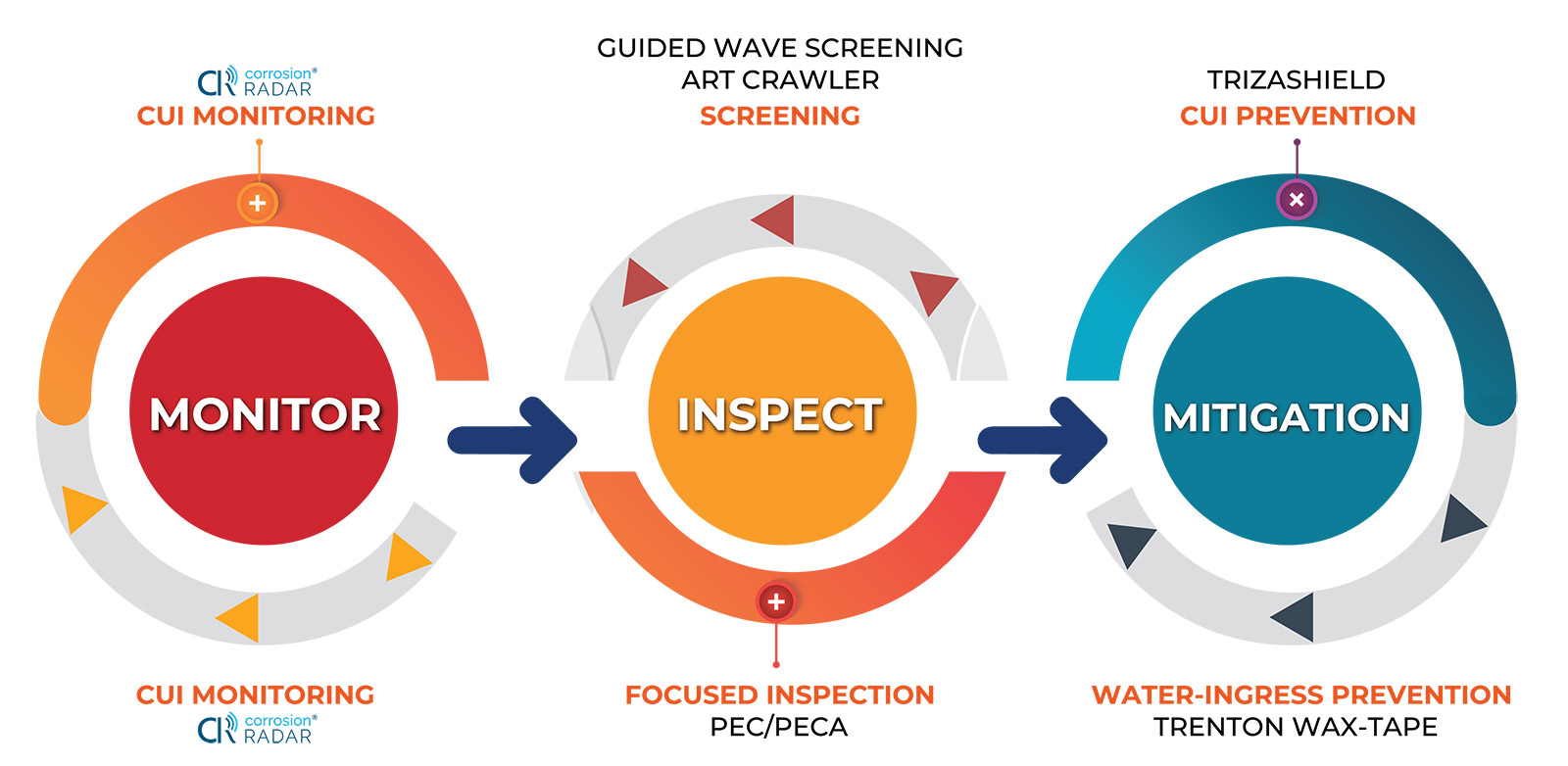

IEV’s CUIMS is an integrated and intelligent solution for managing Corrosion Under Insulation (CUI). It combines cutting-edge technologies such as embedded sensors, wireless data transmission, intelligent software platforms, predictive analytics, robotics, smart CP-based protection systems. CUIMS is structured around three core pillars:

- Monitor: Real-time remote sensing using CorrosionRADAR’s distributed sensors to detect moisture ingress and early-stage corrosion beneath insulation.

- Inspect: Targeted, data-driven inspections using guided wave ultrasound, PEC, and robotic tools to validate sensor alerts and assess asset condition with minimal disruption.

- Prevent: Deployment of advanced protective strategies including cathodic protection-based protection system (e.g. Trizashield™), thermal insulation upgrades to mitigate further corrosion and extend asset life.This comprehensive framework enables proactive, risk-based corrosion management, significantly reducing maintenance costs, improving safety, and minimizing unplanned shutdowns.

Info Pack

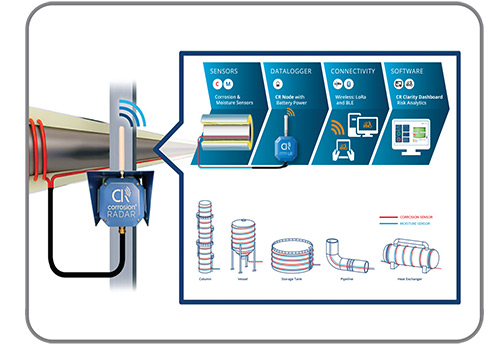

MONITOR : CorrosionRADAR – Remote Monitoring System for CUI

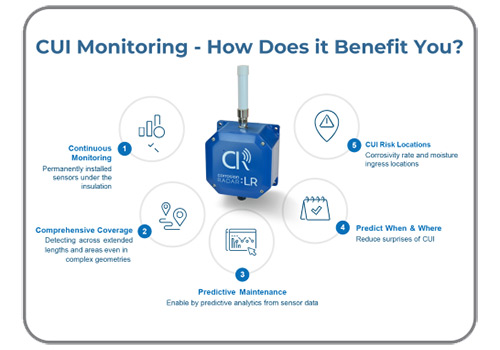

CorrosionRADAR is a state-of-the-art, continuous monitoring system designed to predict the Corrosion Under Insulation (CUI) Risk. It combines advanced sensor technology with predictive analytics to determine when and where corrosion will occur. Using permanently embedded smart wire corrosion and moisture sensors connected to proprietary analytics software, to visualise high risk corrosion locations.

System Architecture

- Sensor Cables: Long-range, flexible sensors are installed under insulation along the asset surface. Each sensor covers up to 50 meters, enabling up to 100 meters of monitoring per unit (moisture + corrosion).

- Data Acquisition:

- Battery-powered CR nodes log data and transmit it wirelessly via LoRaWAN connectivity, enabling deployment even in remote or inaccessible areas.

- Hazardous Area Certified: Sensors and electronics are ATEX-certified, safe for use in industrial environments.

Data & Dashboard

- The system captures moisture presence and corrosion risk indicators, localized along the sensor length.

- Advanced analytics and a “Clarity” dashboard translate sensor inputs into actionable insights, using algorithms and API 581-based risk models.

- Users can visualize real-time CUI risk maps and receive alerts when thresholds are exceeded, enabling predictive maintenance and early intervention.

Key Applications

- Cold Duty Systems (e.g. cryogenic lines, chilled storage): Enables continuous monitoring without shutdown.

- Large or Complex Pipe Networks: Replaces random insulation removal with targeted inspections based on live data.

- Hard-to-Access Areas: Monitors pipe racks, elevated lines, or confined spaces with no human entry required.

Key Benefits

- Early Warning System: Predict CUI long before visible damage occurs.

- Predictive Analytics: Enables shift from reactive to predictive integrity management.

- Reduced Costs: Minimizes unnecessary insulation removal and NDT surveys.

- Improved Safety: Reduces scaffold use and exposure to hazardous conditions.

- Digital Integration: Compatible with RBI and asset integrity platforms.

SCREENING: Guided Ultrasonic Long-Range UT (GUL)

GUL is a powerful non-intrusive inspection technique that uses low-frequency guided ultrasonic waves to detect corrosion and wall loss along long sections of pipe—without removing insulation. From a single test point, GUL can screen tens of meters in both directions, offering 100% circumferential coverage.

How It Works

A ring of transducers is temporarily clamped onto the exposed pipe surface (requiring only a small insulation removal zone). The system sends guided waves along the pipe wall; any geometric changes (e.g. corrosion, welds, supports) reflect part of the signal. These echoes are analyzed to identify location and severity of potential damage.

Key Advantages

- Long-Range Coverage: Up to 30 meters in each direction from one ring setup; hundreds of meters per day possible.

- Full Circumferential Screening: Unlike point UT, GUL inspects the entire pipe cross-section, improving detection of CUI hotspots.

- Minimal Insulation Removal: Only a narrow strip is removed to install the ring; no wide-scale cladding removal needed.

- In-Service Operation: Tests can be conducted on live piping, without shutdown or scaffold-intensive prep.

- Detects Hidden CUI: Highly effective at locating corrosion at supports, saddles, and penetrations.

- Non-Intrusive & Safe: No radiation, no need for confined space entry; safer and more efficient.

Key Limitations

- Qualitative, Not Quantitative: Detects location and severity trend; follow-up UT or PEC needed for precise wall thickness.

- Limited Sensitivity for Small Defects: May miss small or distributed corrosion; best for identifying moderate-to-severe damage.

- Signal Interference: Flanges, tees, or heavy coatings may reduce inspection range or create blind spots.

- Requires Complementary Tools: Best used as a screening method, not a standalone inspection. It highlights hotspots that must be confirmed through localized NDT.

Role in CUIMS

GUL is a critical tool within IEV’s CUIMS (Corrosion Under Insulation Management Solutions) framework. It enables fast identification of CUI-prone areas over large assets—optimizing maintenance planning, reducing unnecessary insulation removal, and prioritizing targeted follow-up inspections.

Info Pack

INSPECTION: Automated Digital Radiography (ART) Crawler for CUI

The ART Crawler is a robotic inspection tool that uses digital radiography to detect corrosion under insulation (CUI) without the need for insulation removal. It scans along insulated pipelines in real time, producing high-resolution digital X-ray images that reveal external and internal wall loss, moisture presence, and insulation anomalies.

How It Works

- A motorized crawler wraps around the pipe and carries an X-ray source and digital detector panel.

- As it travels, it captures continuous radiographic images—essentially a live “video X-ray.”

- The system visualizes metal loss, trapped moisture, voids, and internal corrosion, even through insulation and cladding.

- Remaining wall thickness can be measured using calibration or comparative techniques.

Key Capabilities

- High-Speed Coverage: Can inspect up to 1.6 km/day, ideal for long pipe runs and large plants.

- In-Service Inspection: Operates on live pipelines, even hot lines—no shutdown required.

- No Insulation Removal: Detects CUI without stripping insulation, saving time and cost.

- Moisture & Void Detection: Moisture trapped in insulation shows as contrast differences in the X-ray.

- Full Circumference Imaging: Provides 360° coverage, including hard-to-reach undersides and support zones.

- Digital Recordkeeping: Produces high-resolution, DICONDE-compliant images for documentation and trend analysis.

Role in CUIMS Workflow

The ART crawler serves as a targeted inspection tool following alerts from sensors or RBI models:

- Confirms presence and location of suspected CUI.

- Creates a corrosion map for follow-up NDT or maintenance.

- Reduces unnecessary insulation removal—saves up to 75% of inspection cost by focusing only on areas with confirmed indications.

- Particularly effective at inspecting supports, saddles, and concealed corrosion zones.

Info Pack

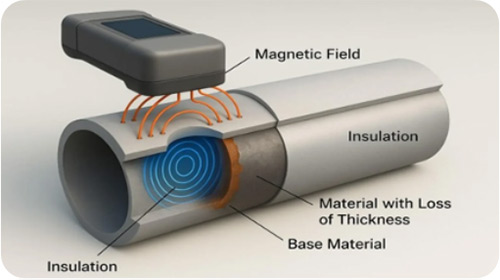

FOCUSED INSPECTION: Pulsed Eddy Current (PEC/PECA) for Targeted Wall

Thickness Measurement

Pulsed Eddy Current (PEC) is a non-destructive electromagnetic technique used to measure wall thickness through insulation, coatings, or cladding—without removing insulation or requiring bare metal contact. It is ideal for quantifying corrosion under insulation (CUI) after an area of concern has been flagged by broader screening tools.

How It Works

- A PEC probe emits a pulsed magnetic field that penetrates the pipe wall. The decay of eddy currents is measured and used to calculate average wall thickness beneath the probe.

- The system works through up to 50–100 mm of insulation and cladding.

- Modern PECA systems (PEC arrays) use multiple coils to cover wider areas and produce C-scan thickness maps for faster, higher-resolution scanning.

Key Advantages

- No Insulation Removal Needed: Works through insulation, paint, and weather jackets—even on hot or asbestos-insulated pipes.

- In-Service Friendly: Operates on live systems without shutdown.

- Fast, Non-Contact Scanning: Can scan several meters per minute, suitable for large surfaces or complex geometries.

- Insensitive to Surface Condition: Not affected by coating, rust, or dirt.

- Safe and Radiation-Free: Unlike radiography, PEC poses no safety hazards or work area restrictions.

Role in CUIMS Workflow

In IEV’s CUIMS strategy, PEC/PECA serves as a quantitative follow-up tool:

- Once CUI risk is identified by sensors, GUL, or ART, PEC is used to measure wall loss.

- Outputs a numerical wall thickness or % metal loss.

- Helps engineers prioritize repair based on severity: e.g. <10% wall loss = monitor; >40% = repair or replace.

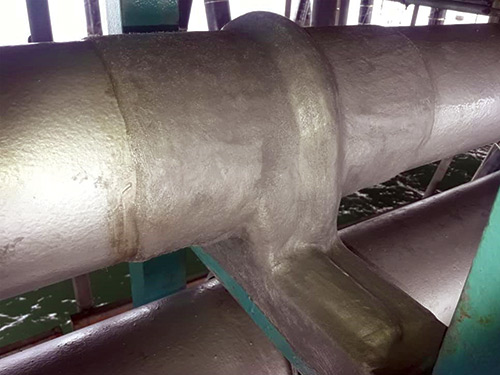

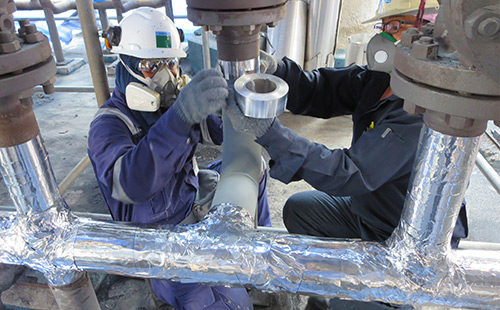

TREAT/PREVENT

Treat moisture pathways and protect steel with durable systems.

WATER-INGRESS PREVENTION

TRENTON MICROCRYSTALLINE WAX-TAPES

- A 3-step anti-corrosion wrap system for pipelining and pipeline, flanges, valve, pipe support, visor, clamps and splash zone structures.

- Long Lasting and easy to apply.

- No special machinery required.

CUI PREVENTION

TRIZASHIELD

- Long-Term Cui Prevention

- A 3-Layer Cathodic Protection with Nanocoating

- 3 Step Application Method

Trizashield is a highly cost-effective CUI protection that combines galvanic zinc, aluminum anode cathodic protection (CP) and corrosion resistant aluminium barrier for piping, vessels and equipment under insulation.

Info Pack

MONITOR

Continuous remote monitoring of repaired areas identified as high-risk under RBI assessments.

Corrosion Under Insulation (CUI) is a major integrity challenge for insulated assets. Corrosion Radar tackles this with advanced sensors, remote monitoring, and predictive analytics for proactive asset management.

- Provides continuous, non-intrusive monitoring of hidden corrosion.

- Enhances safety and reliability by reducing unexpected failures.

- Cuts inspection and maintenance costs through targeted action.

- Uses predictive analytics to forecast risk and prioritize repairs.

- Supports sustainability by extending asset life and minimizing waste.