Asset Integrity Management

We offer a range of disruptive technologies as an individual services or integrated engineering solutions to deliver optimum and cost-effective solutions to inspect, assess, repair and maintain assets.

DIGITAL & CONDITION-BASED MAINTENANCE SOLUTIONS

DIGITAL & CONDITION-BASED MAINTENANCE SOLUTIONS (DCBMS)

IEV’s Digital & Condition-Based Maintenance Solutions (DCBMS) Business Unit delivers an integrated suite of digital technologies that transform how offshore and marine assets are monitored, analyzed, and maintained.

Built on the Sense -Analyse – Act philosophy, the DCBMS ecosystem enables operators to shift from reactive maintenance to predictive, data-driven decision-making -reducing unplanned shutdowns, enhancing safety, and extending asset life.

Info Pack

SENSE – ANALYSE – ACT FRAMEWORK

SENSE: Continuous sensing of corrosion, fatigue, vibration, and environmental data using drones, embedded and wireless sensors.

ANALYSE: Cloud and edge analytics platforms, powered by digital twin technology and predictive algorithms, translate data into actionable insight.

ACT: Risk Assessment, Remote control and automation systems guides optimized interventions and maintain protection with minimal human presence.

Together, these layers create a closed-loop digital integrity management system, combining Poseidon SHM, CorrosionRADAR, Omniflex and IEV PHM into one unified framework.

SHM –STRUCTURAL HEALTH MONITORING & DIGITAL TWIN PLATFORM (POSEIDON)

Poseidon SHM is IEV’s flagship offshore structural monitoring and digital twin platform, developed in Malaysia. Deployed across multiple regions and offshore assets, it provides real-time visibility into the condition and performance of critical structures.

SENSE - Multi-Parameter Structural Sensor Network

Poseidon SHM integrates electrical and optical (FBG-based) sensors into modular Data Acquisition Units (DAQs) to continuously measure:

- Strain & Stress: Localized structural behaviorthrough FBG and electrical gauges.

- Acceleration & Vibration: Global dynamic response and natural frequency trends.

- Tilt & Inclination: Global deformation and settlement trends.

- Temperature & Metocean Parameters: Environmental correlation with structural response.

All data is synchronized through edge processors and transmitted securely to the Poseidon Dashboard, or to on-premise servers for offshore classified sites.

ANALYSE - Digital Twin & Predictive Intelligence

Poseidon’s physics-based digital twin engine processes real-time data through advanced algorithms, providing:

- Automatic natural frequency analysis.

- Fatigue and anomaly detection through model-to-sensor correlation.

- Static and dynamic simulations (Structural In-place, Dynamic, Pushover).

- Visualized 3D digital twins accessible via browser or mobile, integrating data streams with engineering simulations.

ACT - Intelligent Alerts & Remote Integration

- Configurable alarm logic for vibration, stress, or frequency deviation.

- Automated reporting and condition-based maintenance triggers.

- Risk Assessments integration with API-RP2-SIM recommendations

Key Applications

Offshore jackets, FPSOs, wind turbines, marine terminals, bridges, steel and coastal structures.

Key Benefits

- Real-time visibility of offshore asset health.

- Predictive fatigue life assessment and risk alerts.

- Reduces manual inspection manhours by over 60%.

Info Pack

REMOTE CORROSION MONITORING SYSTEM

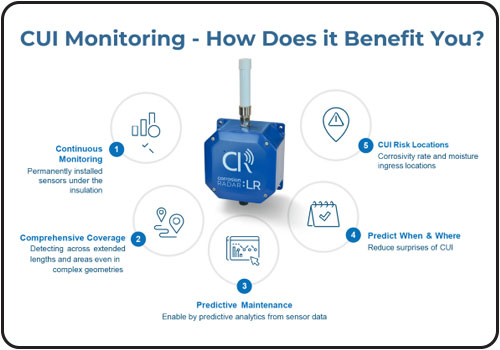

CORROSIONRADAR –DISTRIBUTED CORROSION MONITORING SYSTEM

Corrosion RADARprovides continuous monitoring of Corrosion Under Insulation (CUI) using embedded smart-wire sensors and predictive analytics. The system detects moisture and corrosion activity along long lengths of insulated pipelines and vessels- offering an early-warning capability that replaces conventional random inspection.

SENSE - Smart Wire Sensor Network

- Dual-sensor system: Up to 50m coverage (moisture + corrosion).

- Battery-powered CR Nodes: ATEX-certified with LoRaWANtransmission.

- Easy Installation: Minimal disruption, suitable for complex geometries and hard-to-access assets.

ANALYSE - CLARITY Risk Analytics Dashboard

- Proprietary software that applies DNV RP-109 and API 581-based risk models to compute corrosion probability and moisture severity.

- Generates real-time corrosion risk maps, visualized through a secure, browser-based dashboard.

- Enables predictive maintenance planning and automated reporting.

ACT - Targeted Inspection & Maintenance

- Automatic alerts for threshold exceedance, integrating into RBI strategies.

- Triggers optimized maintenance actions and insulation removal planning.

- Reduces inspection costs by up to 75% through targeted interventions.

Key Applications

Pipelines, process vessels, cold-duty systems, and LNG or refinery assets.

Key Benefits

- Detects corrosion before visible damage.

- Improves inspection precision and safety.

- Integrates directly with digital twin environments.

- Proven in-field reliability (Aramco, ADNOC case studies).

Info Pack

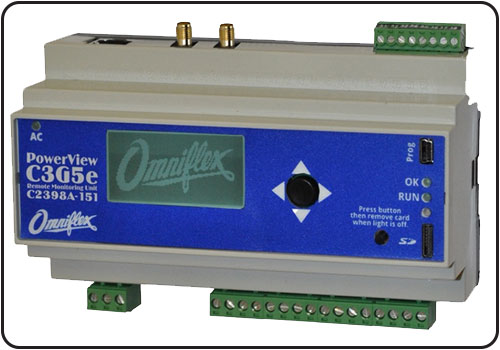

OMNIFLEX –REMOTE CONTROL & CATHODIC PROTECTION AUTOMATION

Omniflex brings remote monitoring, automation, and cathodic protection (CP) control to the DCBMS ecosystem. Under the PowerViewCP range, it provides end-to-end visibility, logging, and control of CP systems through web-based dashboards.

SENSE - Remote Data Acquisition

- Monitors voltage, current, and reference cell data from galvanic or impressed current CP systems.

- Compatible with both new PowertermTR units and legacy CP installations.

- All inputs isolated for high accuracy and safety in hazardous areas.

ANALYSE - Cloud & Data2 Desktop Intelligence

- Real-time visualization and trending via Data2Desktopweb access framework.

- Automatic logging of parameters, instant-off and depolarization tests.

- Enterprise dashboard allows multi-site fleet management and remote audit reporting.

ACT - Remote Control & Adjustment

- Enables remote tuning of CP current outputs and instant-off tests.

- Supports alarms via SMS/email and full web control with secure authentication.

- Reduces on-site visits and improves response time for anomaly management.

Key Applications

Subsea pipelines, jetties, storage tanks, and marine/offshore structures.

Key Benefits

- Remote CP control and compliance testing.

- Cloud-based data logging and reporting.

- Reduced OPEX through automation and minimal site attendance.

- Proven installations in Engen Refinery, Webb Dock, and Sunrise Energy projects.

PIPELINE HEALTH MONITORING (PHM)

IEV’s Pipeline Health Management (PHM) suite provides a complete digitalization framework for long-distance and critical pipelines —integrating drones, IoT sensors, AI analytics, and digital twins into one unified ecosystem.

Structured around IEV’s Sense–Analyse–Act framework, PHM transforms pipeline integrity management from reactive inspection cycles into proactive, data-driven maintenance.

SENSE - Multi-Domain Sensing & Inspection

1. Drone-Based Aerial & Subsurface Inspection (DRONOS SUPERPLATFORM AI)

- A multi-sensor UAV architecture combining LiDAR, GPR, SKIPPER NDT magnetometry, and AI

analytics for full right-of-way (ROW) coverage. - Skipper NDT: High-precision subsurface mapping and pipeline depth-of-cover detection.

- LiDAR: Terrain, erosion, and slope movement analysis.

- GPR: Subsurface void and anomaly detection up to 3–4 m.

- DRONOS.AI: Cloud-based AI platform for 3D digital twin reconstruction, geospatial annotation, and automated intrusion alerts.

- Fulcrum BVLOS/Nested Drones: Enables autonomous long-range patrols for ROW monitoring and encroachment detection.

2. IEV-DFOS: Distributed Fiber Optic Sensing

- Continuous, high-resolution strain, vibration, and temperature monitoring along the pipeline.

- Detects early ground movement, stress build-up, and soil instability.

- Provides meter-level coverage for vibration, strain, and thermal anomalies.

- Enables early warning for leaks, subsidence, or external interference.

3. IEV-GEO & IEV-GFM: Geotechnical & Fault Monitoring

- Real-time geohazard surveillance using Drones and IoT-enabled displacement, strain, and

seismic sensors. - Detects slope movement, fissures, and water-induced instabilities.

- AI-powered Geotechnical Risk Index combines soil moisture, vegetation, and erosion data for

predictive alerts. - Integrates directly into engineering and geotechnical software for quick assessment.

4. IEV-CBM: Critical Bend & Strain Monitoring

- Continuous monitoring at high-risk pipeline bends and road crossings.

- Strain and vibration sensors installed at critical points.

- Predictive analytics identify fatigue accumulation and bending stress before failure.

- Feeds into the Digital Twin for automated risk visualization and maintenance prioritization.

5. IEV-CP: Cathodic Protection Monitoring

- Remote monitoring and control of galvanic and impressed-current CP systems.

- 24/7 cloud visibility of voltage, current, and reference readings.

- Remote testing (Instant Off, Depolarisation, Interference).

- Automated alerts for CP degradation trends.

- Integrated with PowerViewCP system by Omniflexfor field-proven reliability.

ANALYSE - Digital Twin & Predictive Intelligence

1. AI-Driven Data Fusion

- All sensing inputs —structural, geotechnical, corrosion, and aerial —converge into a

unified platform. - Predictive geohazard models for early threat identification.

- Integration with RBI (Risk-Based Inspection) frameworks for compliance.

2. 3D Digital Twin Visualization

- Converts multi-sensor data into interactive 3D models of the pipeline and its

environment. - Enables what-if scenario simulations for landslide, subsidence, or deformation risks.

- Accessible via secure web dashboards —“one truth” shared across engineering,

operations, and management teams.

ACT - Intelligent Control, Alerts & Decision Support

1. Automated Alerts & Decision Layer

- AI-driven threshold monitoring for vibration, strain, or geotechnical anomalies.

- Instant alerts sent to operations teams with GPS location and image data.

- Trigger drone inspections or field deployment directly from the dashboard.

Key Applications

Onshore gas transmission pipelines, offshore and coastal tie-ins, urban buried pipelines and ROW surveillance, aging pipelines operating beyond design life.

Key Benefits

- Continuous, 24/7 Visibility: Full-spectrum monitoring of structural, corrosion, and geotechnical conditions.

- Predictive Risk Management: Detect and act before pipeline deformation, corrosion, or slope failure.

- Reduced OPEX: Minimized inspection frequency and emergency repairs.

- Enhanced Safety: Eliminates manual patrols in hazardous terrain.

- Unified Ecosystem: Drone + IoT + AI + Digital Twin + CP control – all in one platform.