Repair and requalification of offshore oil and gas platforms is a complex and costly activity, involving a wide range of skillsets, knowledge and experience from both structural engineers and marine operations personnel.

IEV’s latest generation of MGP, known as the MGP-i, is designed with “self-cleaning”, “typhoon-proof” and “impact-proof” features for applications in the wave zone to withstand extreme sea conditions. The MGP-i can be applied in areas which are subjected to constant impact forces against obstructions such as structural members at the sea deck level, crossed braces and other auxiliary components. This patented product can be retrofitted from the topside to remove existing marine organisms and prevent its regrowth in one single deployment. Effective on offshore platforms, wind farms, jetties and terminals, the MGP-i can be installed on both new and existing facilities.

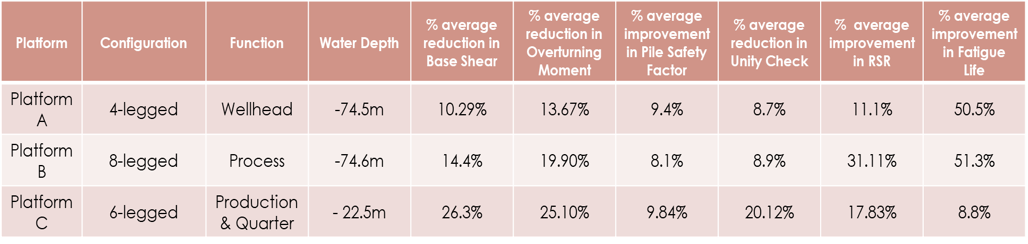

IEV can offer a study called Marine Growth Sensitivity Study (MGSS) to analyse and quantify the benefits of installing MGP-i on the wave zone of specific structures. The results of MGP-i application on typical process, wellhead, production and accommodation platforms are summarised in the following table:

With such significant gains in structural benefits, the MGP-i application is an effective way to recertify the platforms for “Fitness for Service” with reduction in hydrodynamic loads, allowing for both Life Extension and increase in Structural Capacity of offshore assets. Similarly, installation of MGP–i on new built platforms will directly result in lowering overall substructure weight, and consequently, fabrication and installation costs.

Within days of installation, the MGP-i remove existing marine organisms and permanently maintain a zero-growth profile throughout its life, and in doing so it reduces the drag coefficient Cd to that of a smooth profile. This zero-growth profile achieved on structures in the wave zone offers a trade-off benefit and allows the thickness of marine fouling below the wave zone to grow even beyond its design allowances without affecting the structural integrity of platforms. This leads to either reduction in cleaning frequency or complete elimination of cleaning requirements. As it is not necessary to deploy divers and vessels to achieve this permanent change in marine growth profile, the MGP-i represents the world’s lowest cost structural integrity management (SIM) solution commercially available to date.

The MGP was recognised in API RP 2SIM Recommended Practice for Structural Integrity Management of Fixed Offshore Structures, as a measure to reduce hydrodynamic loads: “Such measures may include installation of sliding marine growth preventers and/or adding periodical removal to the SIM program for the platform” (Section 13.3.4.2.3, pg 53, API RP 2SIM, First Edition of November 2014 publication).

Manufactured in Malaysia for over 30 years now, more than 33,000 MGPs have been installed on over 500 new and existing offshore structures worldwide. Since the launch of MGP-i in Year 2014, more than 1,200 MGP-i units have been installed on over 70 offshore structures and jetties.

For further information on the MGSS, please fill out the following enquiry form.