PROJECT BRIEF

The COVID pandemic brought on challenges of sorts forcing organisations to rethink conventional methods of executing projects in the offshore oil and gas industry. One such project awarded to IEV during the pandemic year when Movement Control Orders forced us to “re-engineer” our deployment strategy.

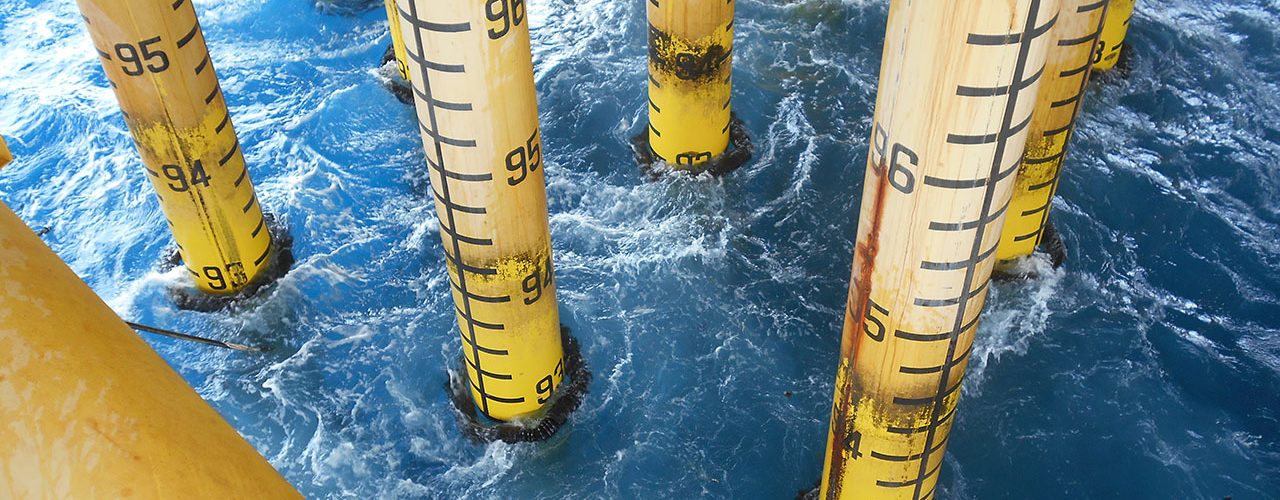

In 2020, IEV (Malaysia) Sdn Bhd received the 2nd-phase award for the scope of assembly and installation of sixty-seven (67) units of Anti-Impact Marine Growth Preventers (MGPs) along with one technical representative on a platform offshore Sabah in Malaysia. In view of the movement control orders in place that restricted the number of working days, the MGPs were delivered as pre-assembled to Client’s warehouse in Labuan. However, during the scheduled installation period, 20 October to 1 November 2020, stricter border controls were imposed causing delays in personnel mobilisation. With the campaign on-going, IEV team promptly deployed a remote monitoring system to train the Client’s RAT personnel to install and verify each installation with video and photographic evidence.

The pre-assembled MGPs eased the delivery and deployment of the MGPs with a simple “drop-and-go” solution. The quick conversion to remote installation, enabled the campaign to be completed within the scheduled period. Traditionally the MGP is assembled under the purview of the IEV Technical Representative at site. As the saying goes, “Necessity is the mother of invention”, the success of this project allowed IEV to extend the outreach of delivery and installation of MGPs through an efficient assembly system and the internet of things.

MGPs are IEV’s patented technology, designed maintain an offshore structure with “zero marine growth” profile and operate at reduced environmental loads. This consequently increases the structural capacity of the platform, allowing it to increase its Reserved Strength Ratio (RSR) and significantly prolong its operating and fatigue life.

IEV’s Typhoon-proof and Self-cleaning MGPs for offshore platforms is designed for 10-year service life and is manufactured by strict ISO standards. To date IEV has installed MGPs on over 500 offshore structures worldwide.

Read more on this project at, https://www.iev-group.com/asset-integrity-management/structural-integrity-solutions/

To learn more on MGP for offshore platforms visit https://www.iev-group.com/adding-significant-strength-life-offshore-structures-ocean-powered-marine-growth-preventers/