IEV Appointed As Exclusive Distributor For Alocit Coatings In 21 Countries In Asia Pacific Region

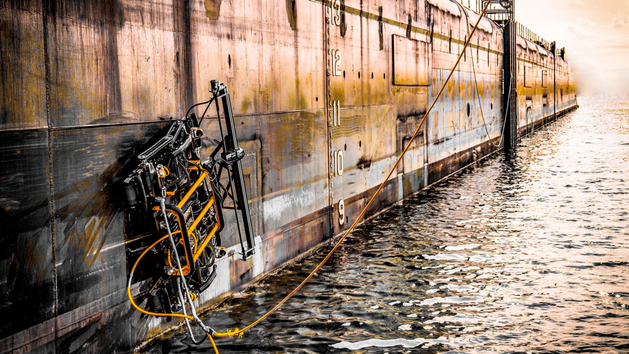

Alocit Coating is a specialised coating system that can be applied on both dry and wet conditions such as splash zone areas of offshore structures and marine vessels IEV has partnered with Alocit International Limited, a UK-based company, to distribute Alocit Coatings, a unique coating system that can be applied on both steel and concrete […]